Last weekend we mobilized two of our engineers to attend a vessel in Ghent, Belgium. They had some issues with their Servomex 1800 oxygen analyser, which was connected to the vessel’s Inert Gas Generator. Our engineers are highly skilled when it comes to the Servomex 1800 unit and we carry a full stock of spare parts, allowing us to act fast and accordingly exactly like this specific case.

Last weekend we mobilized two of our engineers to attend a vessel in Ghent, Belgium. They had some issues with their Servomex 1800 oxygen analyser, which was connected to the vessel’s Inert Gas Generator. Our engineers are highly skilled when it comes to the Servomex 1800 unit and we carry a full stock of spare parts, allowing us to act fast and accordingly exactly like this specific case.

The 1800 unit on board was used on a Kaeser nitrogen generator, used to create inert gas for use in the cargo tanks. This is quite an alternative way to create inert gas; usually fuel is burned to produce inert gas. Inert gas contains less than 3.5% oxygen, making it inflammable and therefore very suitable to cover up flammable cargo. Due to this, the cargo is unable to ignite since there is too little oxygen in the air.

Get in touch with us

Spark + fuel but no (or not sufficient) oxygen still doesn’t give a bang. The 1800 unit measures the O2 level in the inert gas in order to check proper functioning on the generator and whether the outputted gas is actually inert. Therefore the oxygen analyser on an Inert Gas System or Generator is very important, to monitor if the produced gas is in fact really inert. In case the oxygen level is too high but not correctly analysed.

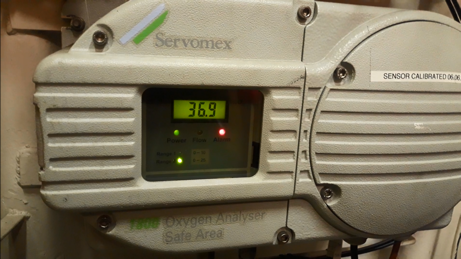

The 1800 unit was showing a 37.3% oxygen (O2) level, even when provided pure air. Remarkable, since air only contains 21% oxygen and therefore a higher reading tells us there is something wrong.

Our engineers fully inspected the unit according to our procedures and found the measuring cell on the unit being faulty. After our engineers replaced the measuring cell, the unit was thoroughly checked together with the vessel’s crew and found in proper working condition again.